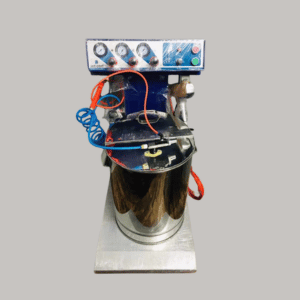

SP-786 Powder Coating Machine Pakistan — Professional Manual System

The SP-786 powder coating machine Pakistan market relies on for consistent finishing quality is a compact, manual electrostatic system built for small to mid-batch production. The kit combines a high-efficiency spray gun, a fluidizing hopper for smooth powder delivery, and a kV/µA-adjustable controller that lets operators fine-tune charge and flow for different part geometries. Fabrication shops choose the SP-786 for its stable transfer efficiency, quick color changes, and low maintenance—delivering clean, uniform film builds with less waste.

Why Choose the SP-786

-

Reliable electrostatic charge for even coverage and reduced rework

-

Hopper-fed powder delivery for steady flow and fewer clogs

-

Adjustable kV/µA to match powders, parts, and Faraday-effect areas

-

Fast teardown and cleaning for frequent color changeovers

-

Small footprint and plug-and-play installation for busy workshops by powder coating machine Pakistan

Powder Coating Machine Price in Pakistan (SP-786)

Actual price in Pakistan depends on your configuration—nozzle set, hose length, injector type, and hopper capacity. Share your job size, finish requirements, and production rate, and we’ll tailor the SP-786 package and quote accordingly.

Recommended add-ons that can influence cost: additional nozzles (conical/flat), longer powder hoses, spare injectors, moisture traps, and air regulators. To receive the latest powder coating machine price in Pakistan, request a same-day quote via WhatsApp.

Powder Coating Machine Supplier in Pakistan — Rafiq Traders

Choosing the right supplier in Pakistan is as important as choosing the right machine. Rafiq Traders provides local stock availability, responsive after-sales support, and quick access to essential spares. powder coating machine Pakistan Our team assists with setup guidance, recommended starting parameters, and best-practice maintenance—so your SP-786 runs reliably and downtime stays low.

What you get with a local supplier in Pakistan:

-

Prompt delivery to major cities and industrial zones

-

Warranty handling and guided troubleshooting

-

Ready spares for guns, hoses, injectors, and nozzles

-

Practical training tips and operating checklists

Specifications & Power Requirements

-

Model: SP-786 (manual electrostatic powder coating machine)

-

Powder Feed: Hopper-fed with fluidizing lid

-

Spray Gun: Single-gun setup with quick-connect cable and powder hose

-

Controller: Adjustable kV/µA, on-board gauges and air regulators

-

Hopper Capacity: Typically 20–50 L (package dependent)

-

Input Power: 220–240 V AC (Pakistan standard)

-

Starting Parameters: ~60–70 kV with low µA; target 60–80 μm film build

Air Quality: Use dry, regulated compressed air with an effective moisture trap. Stable air and clean lines are essential for a consistent powder cloud and superior transfer efficiency.

What’s Included (Typical SP-786 Kit)

-

Electrostatic spray gun with trigger leads and cable

-

Powder hose and injector assembly

-

Fluidizing hopper with pick-up tube and lid

-

Control panel with kV/µA adjustment and pressure gauges

-

Standard nozzle set (conical/flat) and basic maintenance kit

Note: Packages can be customized with additional nozzles, extended hoses, and spare injectors to match your throughput and finish targets.

Quick Start — Practical Setup Guide

-

Grounding: Verify reliable grounding for the workpiece and booth.

-

Air & Powder: Adjust hopper fluidization; ensure powder is dry and free-flowing.

-

Controller Settings: Begin around 60–70 kV with low µA; reduce kV slightly for recesses/Faraday areas.

-

Gun Distance: 15–25 cm typical; adjust angle to improve coverage in difficult areas.

-

Curing: Follow powder manufacturer’s cure schedule; confirm oven temperature uniformity with test panels.

Applications & Use Cases

-

Fabrication parts: frames, brackets, fixtures

-

Railings, fencing, and shop furniture

-

Under-body and utility components (primer/base coats)

-

Jigs, racks, and maintenance tooling

-

Retail and workshop displays seeking durable finishes

Related Equipment & Upsells

For better throughput and finish control, pair the SP-786 with:

-

Powder Coating Booths (efficient recovery and overspray control)

-

Curing Ovens (even bake and reliable cure)

-

Powder Spray Guns & Nozzles (spares and specialty tips)

FAQs — Price, Supplier, and Setup

What is the SP-786 price in Pakistan?

Pricing varies by configuration. Request a tailored quote for your parts, finish, and volume.

Do you provide installation and after-sales support?

Yes—Rafiq Traders supports customers as a local supplier in Pakistan with guidance, warranty handling, and essential spares.

Is the SP-786 suitable for frequent color changes?

Absolutely. The manual design and simple teardown make rapid changeovers straightforward.

What starting settings should I use?

Begin near 60–70 kV with low µA, target 60–80 μm film build, and adjust for geometry and powder type.

What power and air do I need?

220–240 V AC and dry, regulated compressed air with moisture control.

Qasim –

Recommend!