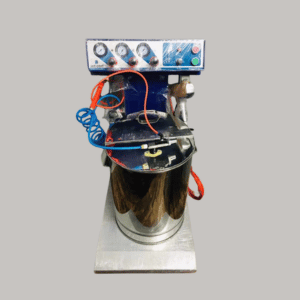

SP-501 Powder Coating Machine Pakistan

The SP-501 powder coating machine Pakistan market chooses for dependable results is a compact, manual electrostatic unit designed for small to mid-batch production. A high-efficiency spray gun, fluidizing hopper, and a digital, kV/µA-adjustable controller give operators precise control over charge and flow, helping achieve uniform film builds with reduced rework and waste. For fabrication shops handling frequent color changes, the SP-501 offers quick teardown, stable transfer efficiency, and day-to-day reliability.

Why Choose the SP-501

-

Consistent electrostatic charging for smooth, even coverage

-

Hopper-fed delivery for steady powder flow and fewer clogs

-

Digital controller with adjustable kV/µA for different geometries and powders

-

Fast color changeovers and low maintenance overhead

-

Compact footprint; straightforward installation and operation

Powder Coating Machine Price in Pakistan (SP-501)

Your price in Pakistan depends on configuration Powder Coating Machine Pakistan —nozzle set (conical/flat), hose length, injector type, and hopper capacity. Share your part sizes, finish target, and production rate; we’ll tailor the SP-501 package and quote accordingly.

Common cost drivers: additional nozzles, longer hoses, spare injectors, moisture traps, and air regulators. For an accurate powder coating machine price in Pakistan, request a same-day quote via WhatsApp.

Powder Coating Machine Supplier in Pakistan — Rafiq Traders

Selecting a reliable supplier in Pakistan ensures smooth commissioning and uptime. Rafiq Traders supports the SP-501 with local stock, Powder Coating Machine Pakistan responsive after-sales service, and essential spares. We provide setup guidance, recommended starting parameters, and maintenance best practices—so your line runs efficiently with minimal downtime.

What you get with a local supplier in Pakistan:

-

Prompt delivery across major cities and industrial zones

-

Warranty handling and guided troubleshooting

-

Ready spares: guns, injectors, hoses, and nozzles

-

Practical training tips and checklists for operators

Specifications & Power Requirements (SP-501)

-

Powder Feed: Hopper-fed with fluidizing lid

-

Spray Gun: Single-gun setup with quick-connect hose and cable

-

Controller: Digital display; adjustable kV/µA; on-board gauges & regulators

-

Hopper Capacity: Typically 20–50 L (package dependent)

-

Input Power: 220–240 V AC (Pakistan standard)

-

Starting Parameters: ~60–70 kV with low µA; target 60–80 μm film build

Air Quality: Use dry, regulated compressed air with an effective moisture trap. Clean, stable air is critical for a consistent powder cloud and high transfer efficiency.

What’s Included (Typical SP-501 Kit)

-

Electrostatic spray gun with trigger leads and cable

-

Powder hose and injector assembly

-

Fluidizing hopper with pick-up tube and lid

-

Digital control panel (kV/µA) with pressure gauges

-

Standard nozzle set (conical/flat) and basic maintenance kit

Quick Start — Practical Setup Guide

-

Grounding: Ensure robust grounding for workpiece and booth.

-

Air & Powder: Adjust hopper fluidization; keep powder dry and free-flowing.

-

Controller: Start around 60–70 kV with low µA; reduce kV for recesses/Faraday areas.

-

Gun Distance: 15–25 cm typical; angle for coverage in difficult corners.

-

Curing: Follow powder manufacturer’s schedule; verify oven uniformity with test panels.

Applications & Use Cases

-

Fabrication parts: frames, brackets, fixtures

-

Railings, fencing, shop furniture and displays

-

Utility/under-body components (primer/base coats)

-

Jigs, racks, and maintenance tooling

Related Equipment

Pair the SP-501 with:

-

Powder Coating Booths (overspray control & recovery)

-

Curing Ovens (even bake and reliable cure)

-

Powder Spray Guns & Nozzles (spares and specialty tips)

FAQs — SP-501 Powder Coating Machine Pakistan

1) What is the SP-501 powder coating machine price in Pakistan?

Price depends on configuration (nozzles, hose length, hopper size, extras). Share your requirements on WhatsApp for a same-day price in Pakistan quote.

2) Who is the supplier in Pakistan for SP-501?

Rafiq Traders is a local supplier in Pakistan with stock, warranty handling, and essential spares for the SP-501 powder coating machine.

3) Is SP-501 manual or automatic?

SP-501 is a manual electrostatic powder coating machine—ideal for small to mid-batch production and frequent color changes.

4) What power and air are required?

220–240 V AC. Use dry, regulated compressed air with a moisture trap to keep powder flow stable.

5) What are the starting kV/µA settings?

Begin around 60–70 kV with low µA. Reduce kV slightly for recesses/Faraday areas; aim for 60–80 μm film build.

6) What’s included with the SP-501 kit?

Electrostatic spray gun, powder hose + injector, fluidizing hopper, digital kV/µA controller with gauges/regulators, and a standard nozzle set.

7) Which powders are compatible?

Polyester, epoxy, epoxy-polyester hybrids, and polyurethane powders. Always cure per the powder manufacturer’s schedule.

8) How fast can I change colors?

The SP-501 is designed for quick color changeovers—simple teardown/cleanup minimizes downtime between batches.

9) Do you provide installation or training?

Yes. As a local supplier in Pakistan, Rafiq Traders provides setup guidance, recommended parameters, and operating checklists.

10) What affects the powder coating machine price in Pakistan?

Nozzle packs, hose length, injector type, hopper capacity, and optional air treatment (moisture traps/regulators) influence final pricing.

11) What maintenance does SP-501 need?

Keep air lines dry, clean nozzles/injector regularly, check grounding, and inspect hoses/cables for wear. Replace consumables as needed.

12) Can SP-501 be used with booths and ovens I already have?

Yes—SP-501 integrates with most powder coating booths and curing ovens. Ensure booth grounding and oven temperature uniformity.

13) What warranty and spares are available in Pakistan?

Rafiq Traders handles local warranty support and keeps common spares (guns, hoses, injectors, nozzles) for quick turnaround.

14) Is SP-501 suitable for outdoor parts and heavy fabrication?

Yes—paired with the right powder (e.g., TGIC polyester for outdoor), SP-501 delivers durable finishes on railings, frames, and shop fixtures.

15) How do I improve transfer efficiency and reduce waste?

Use dry air, correct gun-to-part distance (15–25 cm), proper grounding, and match kV/µA to geometry. Keep hopper fluidization steady.

16) Can I order the SP-501 outside major cities?

Yes—nationwide delivery is available. Share your location for lead times and freight options.

Qasim –

Recommend!