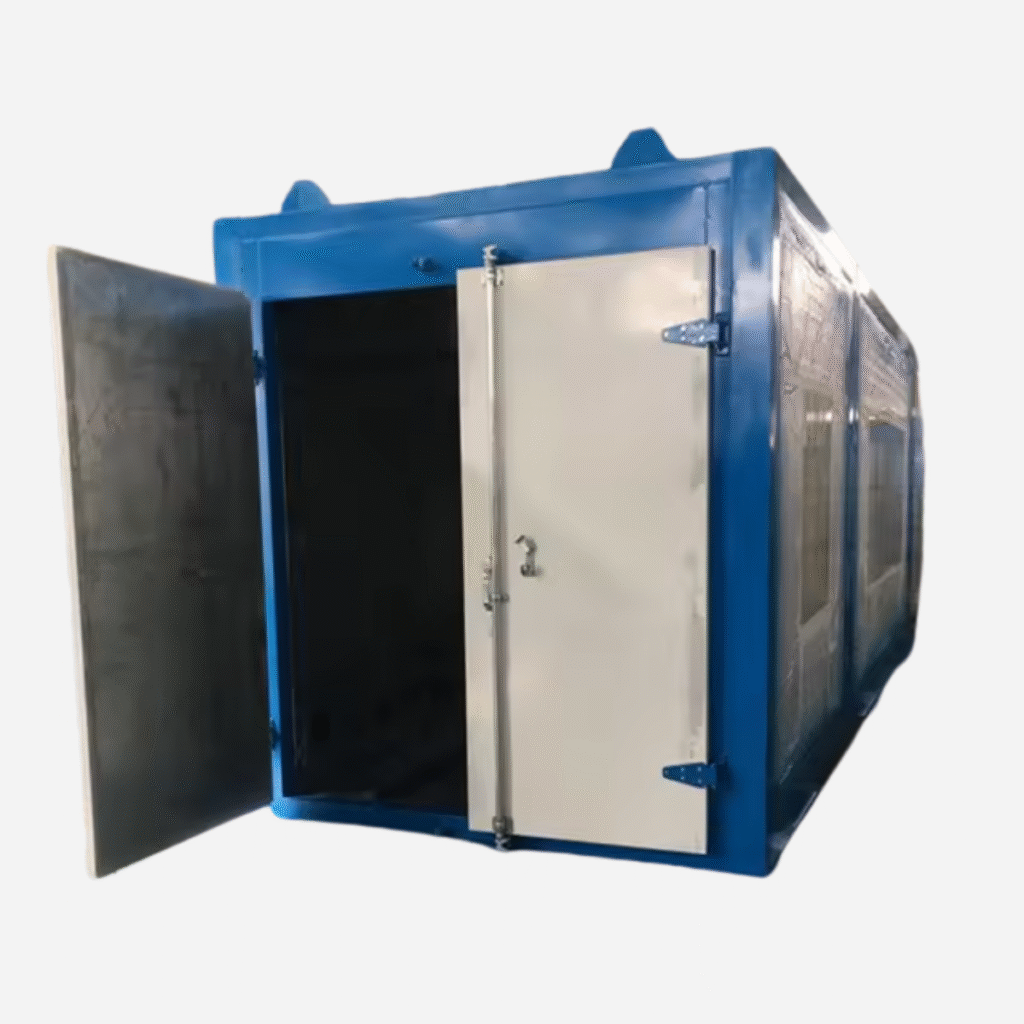

Custom Powder Coating Ovens in Pakistan — Engineered for Consistent Cures

Rafiq Traders designs and supplies powder coating ovens in Pakistan that match your parts, volumes, and floor space. Whether you need a compact batch oven for job-shop work, a walk-in/drive-in oven for large frames, or a conveyor oven for continuous lines, we build to size with the right heat source, airflow pattern, and control package. The result: uniform film builds, reliable cross-linking, and fewer reworks—exactly what serious buyers of powder coating ovens in Pakistan expect.

Why Our Powder Coating Ovens Stand Out

-

Uniform temperature profiles for even cure (verified with test panels)

-

Efficient insulation & robust sealing to reduce heat loss and operating cost

-

Precise PID control with multi-point thermocouples and safety interlocks

-

Flexible heat sources: electric, gas, or diesel (based on availability/cost)

-

Scalable formats: batch, walk-in/drive-in, or conveyor for higher throughput

-

Local after-sales support from a trusted supplier in Pakistan

Built to order: Share usable space (W×H×D in ft), target temperature (°C), and cycle time. We’ll spec the oven to your parts and production goals—because the best powder coating ovens in Pakistan are the ones engineered around your process.

Price & Lead Time — Powder Coating Oven Price in Pakistan

Final powder coating oven price in Pakistan depends on chamber size, insulation thickness, heater capacity (kW/BTU), airflow design, control package, and chosen heat source (electric/gas/diesel). Send a layout or simple sketch and we’ll return a line-item quote with realistic delivery timelines.

Key cost drivers

-

Internal dimensions (W×H×D) and max setpoint (°C)

-

Heater capacity & heat source (electric/gas/diesel)

-

Air circulation (ducting, fans, baffles) and temperature uniformity spec

-

Controls (PID, ramp/soak, data logging, over-temp protection)

-

Throughput style (batch/walk-in/drive-in vs conveyor)

CTA: WhatsApp for today’s quote — include part envelope, desired cycle time, and preferred heat source to size the ideal powder coating oven in Pakistan.

Options & Configurations

-

Formats: Batch · Walk-In/Drive-In · Conveyor

-

Heat Sources: Electric · Gas · Diesel (choose for availability and OPEX)

-

Controls: PID with SSR/contactor, ramp/soak profiles, over-temp cutoff, data logging

-

Airflow: Forced convection, balanced supply/return, adjustable recirculation

-

Build: Mineral-wool/ceramic insulation, high-temp gaskets, reinforced panels

-

Access: Single/double doors, floor tracks/ramps, sight windows, pass-through

Specification Template (example — customized per order)

| Parameter | Typical Range / Option |

|---|---|

| Internal Size (W×H×D, ft) | 3×3×4 · 6×6×8 · 8×8×12 · 10×10×20 · custom |

| Max Temperature | 180–220 °C (powder cure), higher on request |

| Heat Source | Electric / Gas / Diesel |

| Heater Capacity | Sized to part mass & cycle time (kW or BTU/h) |

| Air Recirculation | Forced convection, balanced ducts & baffles |

| Temperature Control | PID, ramp/soak, over-temp, multi-TC inputs |

| Insulation | 100–150 mm typical; low leakage, high efficiency |

| Power | 220/380 V · 1-ph/3-ph (Pakistan) |

| Safety | Door interlocks, E-stop, over-temp protection |

We tune heater capacity to your cycle time and part mass—so your powder coating ovens in Pakistan cure fast without hot spots or cold corners.

Supplier in Pakistan — Local Expertise, Real Support

As a powder coating oven supplier in Pakistan, Rafiq Traders helps with sizing, heat-source selection, and commissioning. We also provide after-sales support, spare parts, and quick troubleshooting—so your powder coating ovens in Pakistan keep running at spec.

Share for a fast, accurate proposal

-

Parts’ max dimensions & batch size / line speed

-

Target cure schedule (°C × minutes)

-

Preferred heat source (electric/gas/diesel)

-

Electrical (voltage/phase) and any site constraints

-

Desired delivery window

Use Cases & Industries

-

Job-shops and fabrication (frames, railings, fixtures)

-

OEM and contract coaters (repeatable, documented cures)

-

Production lines pairing booths + ovens for turnkey cells

-

Maintenance & MRO looking to standardize cure cycles

FAQs — Powder Coating Ovens in Pakistan

Q1: Do you stock or only build to order?

We build to size on demand. Popular footprints are available for quicker deliveries.

Q2: Electric vs gas/diesel — which is best?

Electric offers tight control and simpler install; gas/diesel can cut running costs for larger powder coating ovens in Pakistan. We size both options.

Q3: How is the powder coating oven price in Pakistan calculated?

Chamber size, heater capacity, heat source, airflow design, and controls define cost.

Q4: What’s a typical cure schedule?

Many powders specify ~180–200 °C metal temperature for 10–20 minutes—follow your powder TDS.

Q5: Can you integrate the oven with our existing booth and conveyor?

Yes—send a layout. We’ll match openings, duct positions, and electrical to your line.

Q6: How do you ensure temperature uniformity?

Balanced ducting, recirculation fans, insulation, and multi-point checks with test panels/data logging.

Q7: Do you provide installation or operator training?

Yes—commissioning guidance, safety checks, and operating checklists are included via our supplier in Pakistan support.

Reviews

There are no reviews yet.